Our medical device design and development services help OEMs scale medical devices and non-classified healthcare components. Applying Design for Manufacturability (DFM) principles to guide materials, tooling, and production from pilot to pre-commercial volumes.

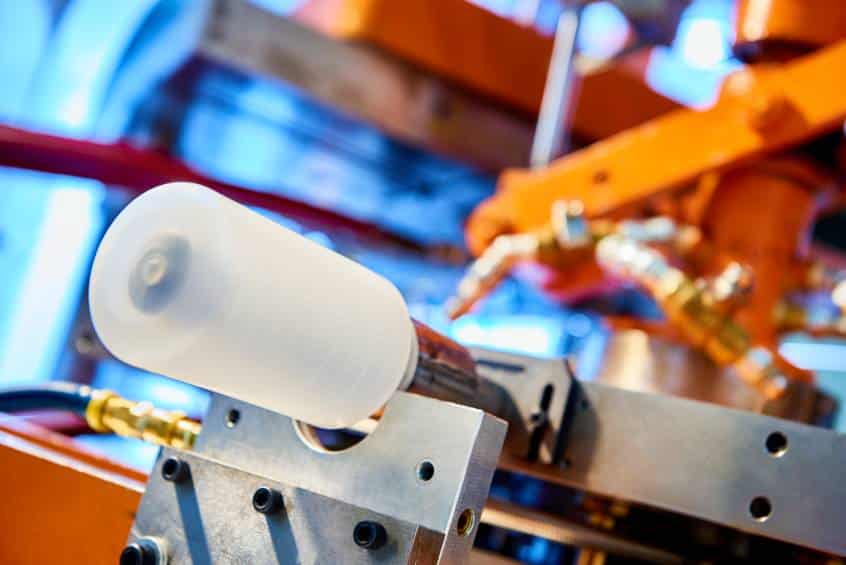

Quick-turn injection molding prototyping accelerates early part evaluation, helping you iterate quickly and make informed decisions sooner.

We use single-cavity aluminum molds and our own Master Unit Die (MUD) frames that help reduce tooling costs for all scales of production.

We offer pilot-run, short-run, and bridge production options to support your project from concept to scale.

From tight-tolerance components to multi-material parts, our team supports complex molding challenges with precision tooling, expert DFM support, and ISO 13485-certified quality systems.

Our medical device design and development services are built on collaboration. In addition to in-house mold development, we partner with trusted vendors to offer SLA, 3D printing, and Rapid Injection Molding (RIM). Whether it’s short-run production or MUD-frame tooling, we expand what's possible—helping OEMs evaluate, refine, and move forward with confidence.

We work closely with OEMs to understand product goals, technical needs, and constraints—helping to shape smart, manufacturable solutions from day one.

From 3D printing to single-cavity tooling, we offer fast-turn options that allow for early testing and iteration—reducing delays and development risk.

Our team builds and refines injection mold designs to optimize part performance, extend tool life, and reduce production costs—tailored to your material and volume needs.

Whether you're building 100 or 100,000 units, our team helps bridge the gap from prototype to full production with cost-effective tooling and clear next steps.

We design with real-world manufacturing and regulatory requirements in mind. As an FDA-registered manufacturer, we specialize in Class I exempt devices and also produce OEM components for Class II and III devices as well as non-classified components.

With advanced metrology and inspection systems, we ensure every design is ready for high-volume, high-compliance production—without surprises.

Our injection mold design and development services include injection and injection blow molding—optimized for precision, compliance, and scale in cleanroom environments.

We operate an 8,000 sq. ft. ISO Class 8 cleanroom with injection molding and injection blow molding, built for high-quality, compliant component production.

From manual to automated assembly in our white room and cleanroom, we deliver finished components with precision, speed, and traceability.

We’re more than a supplier—we’re a strategic partner. As a family-owned company, we move fast, stay flexible, and invest in what matters.

Our collaborative mindset and technical depth help OEMs turn great ideas into manufacturable solutions.

We help OEMs bring complex molded components to life—with the care, speed, and flexibility they depend on.

As a family-owned company, BMP combines the technical depth of a large CMO with the flexibility and responsiveness of a smaller partner. We’re known for investing in capabilities that align with your needs—working side by side to bring your concept to life and scale it effectively. We work closely with OEMs to optimize part geometry, material selection, and tooling strategy from day one.

Yes. Our 8,000 sq. ft. Class 8 cleanroom houses 16 injection molding machines and 4 injection blow molding machines (110–330 ton). We also operate a 5,000 sq. ft. white room for automated assembly and secondary operations—with plans to double our cleanroom footprint to meet growing project demands.